Waterjet Cutting

Waterjet Capabilities

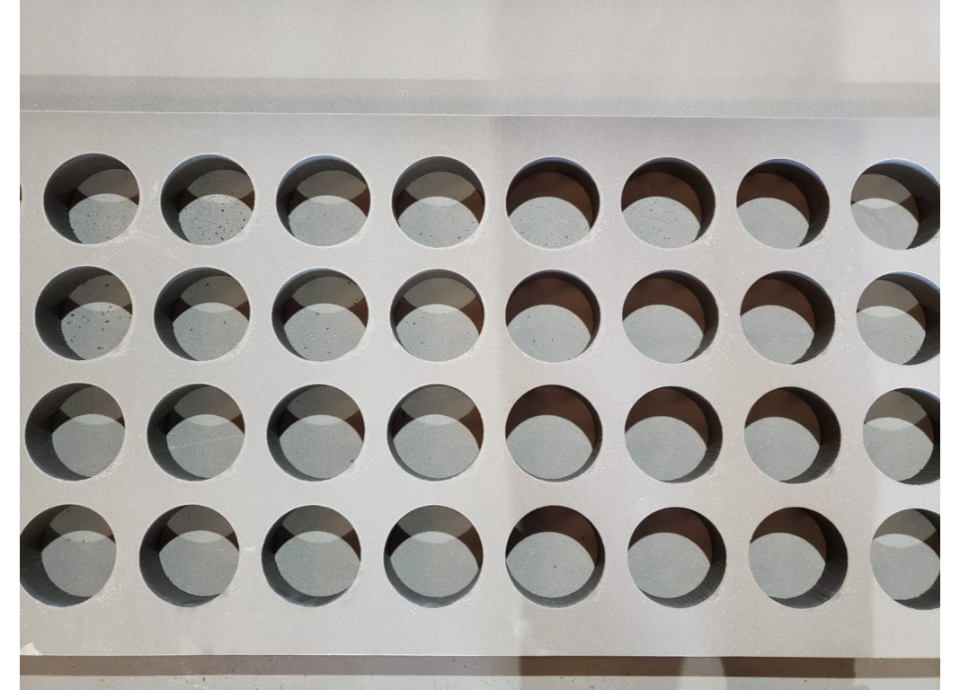

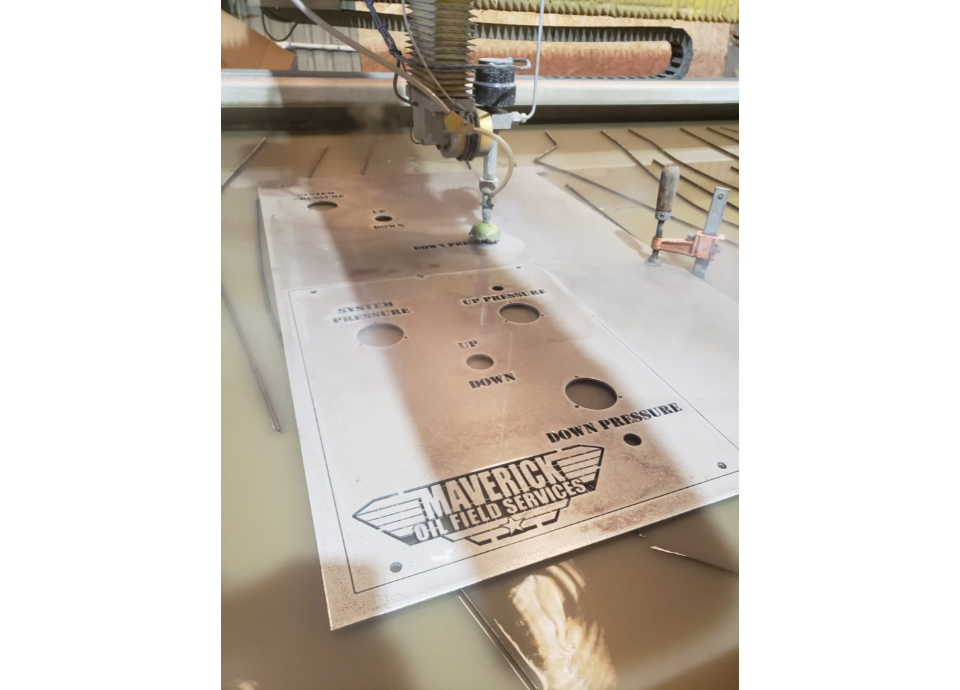

Waterjet, also known as water jet or abrasive jet cutting, is one of Hydro-blade’s processes that directs a high-pressure jet of water and an abrasive substance to cut materials for industrial applications such as machine part manufacturing. Important benefits of waterjet cutting with an abrasive substance include the ability to cut metals, plastics, and woods without increasing the material surface temperature and compromising internal structure of the material; the ability to cut sharp corners, holes, and complex shapes with small inner radii; fast turn-around rates; and minimal material waste thanks to the precise cutting and the narrowness of the nozzle.

Our custom waterjet services offer a cost-effective and on-demand solution for your manufacturing needs. Metal fabrication services range from low-volume prototype to high-volume production runs.

Advantages of Waterjet

Durability

Similar to CNC machining, abrasive waterjet cutting produces highly durable parts well-suited for both prototyping and production. These parts require less testing.

Rapid Turn Around

Combining the latest cutting, bending and punching with automated technologies, Hydro-blade strives to provide quotes within 24 hours and has short lead times.

Material Selection

Steel (mild, stainless, tool, high alloy, hardened), Aluminum, Titanium, Brass, Copper, Bronze Inconel, Hastelloy, Tungsten, Invar, Zirconium Marble, Granite, Glass, Composites, Plastics, Rubber, Foam and more

Scalability

All parts are built on-demand and with lower setup costs compared to CNC Machining. Depending on your needs, order as little as a single prototype to up to 10,000 production parts.

Request a Quote

Other Services

Metal Fabrication

Contract manufacturing and welding as well as metal fabrication services, and we serve a variety of industries.

Contact Us

337-504-2810

Hydro-Blade Waterjets LLC

332 Industrial Pkwy

Lafayette, LA 70508